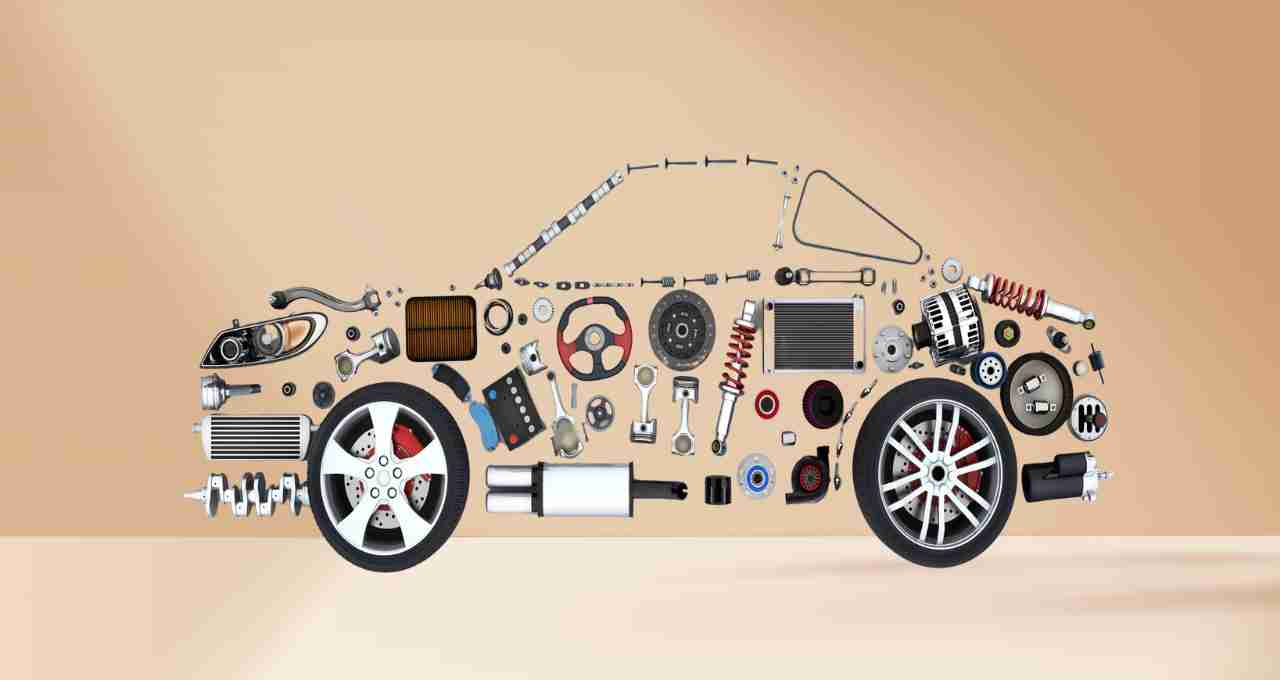

The Indian auto ancillary industry has emerged as a global supplier hub in 2025. Approximately 27% of the industry's production is exported to Europe, ASEAN, the Middle East, and North America. Growing demand, 'Make in India' initiative, and 100% FDI policies have boosted investment and technological improvements. The turnover in FY25 was $80.2 billion, with an expectation of an additional $10 billion investment over the next five years.

Auto Industry: The Indian auto ancillary industry in 2025 is no longer just a vehicle supporting sector but has become a strategic partner in the global auto industry. According to ACMA data, the industry's turnover in FY25 was $80.2 billion, marking an annual increase of 9.6%. 'Make in India', 100% FDI, and shifts in global supply chains have provided Indian manufacturers access to production and investment aligned with global standards. The demand for technologies such as ABS, airbags, and advanced infotainment systems has increased, and the industry's production is estimated to reach USD 3235 billion by FY26.

Global Expansion of the Indian Auto Ancillary Industry

According to data from the Automotive Component Manufacturers Association of India (ACMA), the industry's turnover in fiscal year 2025 was $80.2 billion. This represents a year-on-year increase of 9.6 percent. Over the past five years, the industry size has doubled, maintaining a CAGR of 14 percent. In the future, under the Automotive Mission Plan, the industry's contribution to GDP is estimated to reach 5-7 percent. According to long-term assessments, the industry size could reach $220 billion.

Approximately 27 percent of India's auto ancillary production is exported to Europe, ASEAN, the Middle East, and North America. The strategy to reduce reliance on China (China+1) has brought opportunities for Indian manufacturers.

New Technology and Rising Demand

The rapidly growing urban middle-class population and increasing disposable income in the country have boosted vehicle ownership. People are now demanding high-quality vehicles and advanced technological features. The demand for technologies such as ABS, airbags, and advanced infotainment systems is continuously rising.

'Make in India' and 100 percent FDI policies have provided Indian vehicle manufacturers access to significant investments. Global automakers have invested $37.21 billion in India since 2000, enabling domestic manufacturers to produce goods in line with global standards.

Future Investment and Production Prospects

The Indian auto ancillary industry is estimated to reach a production level of $3,235 billion by FY26. An additional $10 billion investment is expected over the next five years through the PLI scheme. This investment will lead to technological innovation and increased production capacity.

Due to global investment and strategic partnerships, India is becoming a global hub in the auto component sector.

Supply Chain Challenges and Opportunities

Challenges include geopolitical uncertainties, tariff wars, and supply chain disruptions. In such a scenario, only companies with b operational capabilities and those that remain active in the global market will achieve success in the future.

The Indian auto ancillary industry is no longer just a supplier. It is emerging as a strategic and innovative partner in the global auto industry. This strengthens India's automotive identity, and in the future, this sector will play a crucial role in the country's economic and industrial development.