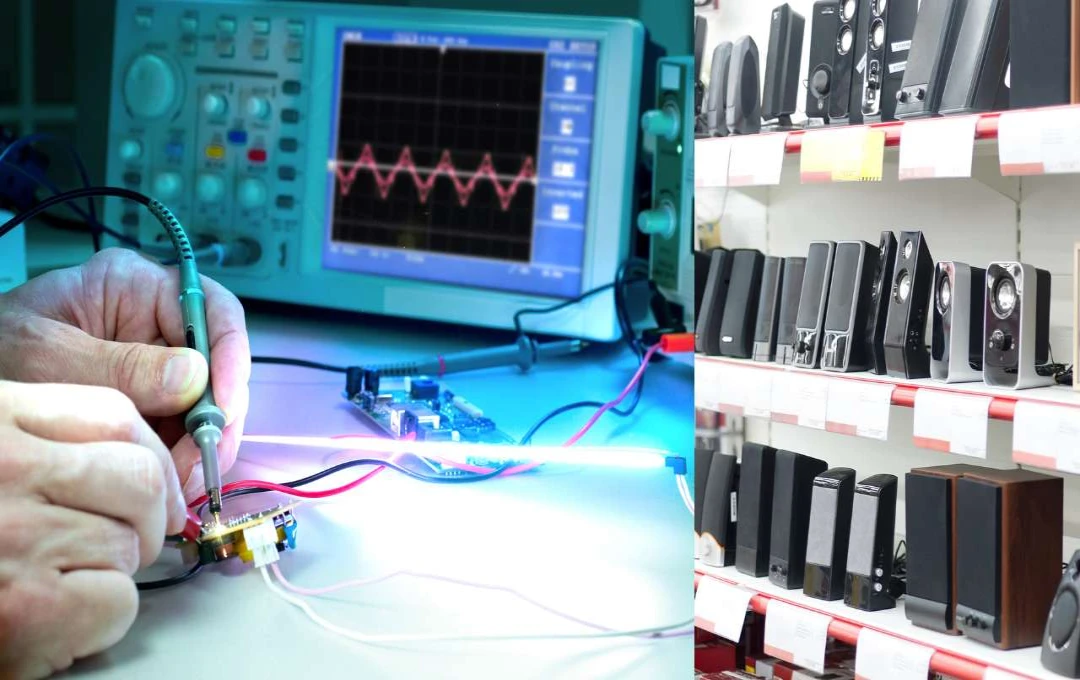

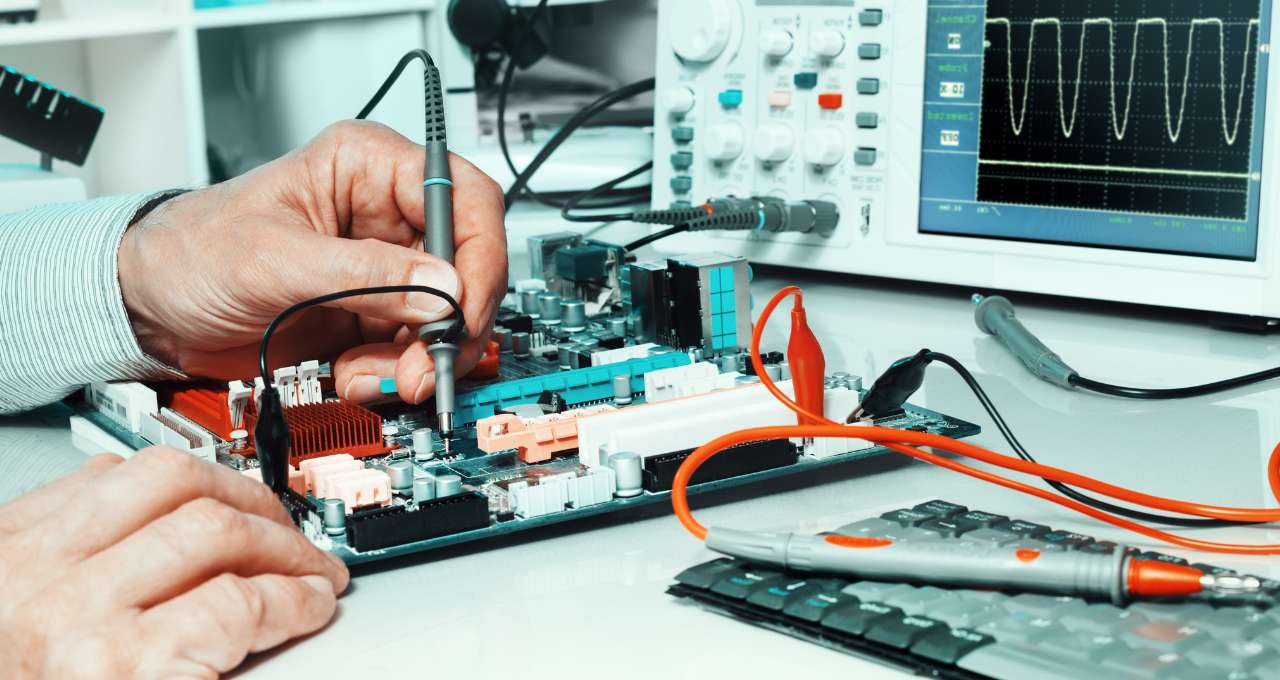

India's Electronics Component Manufacturing Scheme (ECMS) has attracted 249 companies, promising investments exceeding ₹1 lakh crore and 1.42 lakh new jobs. The scheme aims to boost electronics production to $500 billion by 2030, reducing imports and increasing local production.

Electronics Sector: Under the Indian government's 'Make in India' initiative, the Electronics Component Manufacturing Scheme (ECMS) has shown significant success. 249 companies have proposed investments exceeding ₹1 lakh crore, with an estimated creation of 1.42 lakh new jobs. The scheme will run until 2032, aiming to increase electronics production in India to $500 billion in sectors like mobile, TV, laptops, auto electronics, and telecom, thereby reducing imports and enhancing the value of local production.

Objective and Importance of the Scheme

The primary objective of ECMS is to strengthen India's electronics sector and boost investment in industries such as mobile, TV, laptops, auto electronics, and telecom. The government has set a target to reach $500 billion in electronics production by 2030. Of this, 70 percent will come from finished products and 30 percent from components and sub-assemblies.

Currently, India's total electronics production stands at $135 billion, with finished products accounting for 88 percent and components and sub-assemblies contributing only $15 billion. This clearly indicates that India will need to increase its production of components and sub-assemblies by approximately tenfold by 2030.

Company Participation and Investment

The ECMS scheme has generated significant interest in the industry. Alongside electronics companies like Dixon and Foxconn, auto parts manufacturers such as Samvardhana Motherson and Uno Minda have also joined the scheme. Large conglomerates like Tata have also proposed investments under this scheme. Experts believe that even if India achieves $100 billion in production by 2030, it would still be approximately 6.6 times the current production.

Impact on Imports and Production Capacity

Currently, a significant portion of many components required for mobile phones, TVs, laptops, and other devices in India are imported from abroad. For instance, approximately 88 percent of Printed Circuit Boards (PCBs) are imported. Similarly, lithium-ion batteries, displays, and camera modules also rely on imports. The ECMS scheme emphasizes the production of these components within India. If all parts are manufactured domestically, India's profit margin in mobile production would increase from 18 percent to 35-40 percent.

A three-member committee was formed to draft the ECMS. Following this, over 100 meetings were held for approximately 12 months between government officials, industry associations, and companies. Officials visited Taiwan, Japan, and South Korea, and inspected 40-50 factories in India. This provided them with practical experience in production and costs, helping to set investment priorities.

Incentives and Flexibility

The scheme grants companies the flexibility to set their own production targets. Additionally, a 25 percent incentive on capital expenditure (Capex) has been provided, making it easier for small and medium-sized companies to participate in the scheme.

Mobile Production and Export

In fiscal year 2025, the value of mobile production in India was $65 billion, of which $24 billion accounted for exports. Large companies like Apple are increasing production in India, but only 20 percent of their production capacity has been transferred to India so far. This indicates a significant potential for increasing mobile exports from India. The combination of the PLI scheme and ECMS will provide companies with an opportunity to compete in the global market.